Next-generation cost-effective provider of price-competitive concrete mixing plants ?

Inside the exacting universe of erection, productivity and results are critical. To address these necessities, up-to-date erection implements have transformed to provide exceptional capability and trustworthiness. Modern elite development apparatus packages are equipped with advanced systems boosting output and lessening environmental harm. Including strong earth-movers and transporters to flexible hoists and miniaturized devices, these implements are developed to execute the most demanding construction activities with simplicity.

- Refined pressure modules allow for smooth and precise maneuvering, resulting in increased accuracy and reduced downtime.

- Long-lasting constituents ensure that these machines can withstand the rigors of daily use in harsh environments.

- Energy-saving motors minimize the environmental footprint of construction activities.

Concrete Production Units: Developed for Productivity

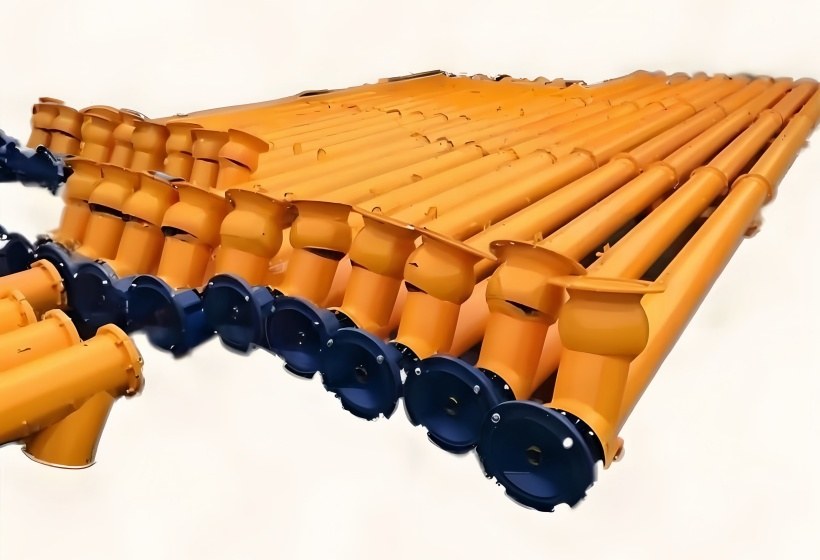

Concrete batch operators perform as the integral drivers of assembly projects, maintaining concrete is composed precisely and consistently. These advanced setups utilize various state-of-the-art innovations to optimize productivity throughout the concrete manufacturing cycle. From the precise assessment of constituents to optimized fusion and emission activities, concrete manufacturing units are constructed to offer excellent concrete complying with exacting standards in present-day erection. By automating necessary steps and decreasing human engagement, these apparatuses confirm stable output while promoting full-scale efficiency.Stabilized Soil Plant Mixers Delivering Durable Foundations

Within the sphere of building, solidity is crucial. When it comes to building durable foundations, stabilized soil mixing plants emerge as a advanced remedy. These versatile machines competently integrate cementitious materials with original substrate, generating a fortified mass resistant to adverse conditions and longevity demands.

Affording extraordinary robustness and longevity, soil stabilizing machines hold key positions in assorted enterprises, embracing parkways, bridges, lanes, and urban/rural establishments. By exploiting the native properties of terrain, these systems present a green strategy for groundwork assembly.

Construction Batch Systems for All Assignments

We acknowledge each development task is individual and calls for custom construction mixtures. Thus, we grant assorted modifiable building material plant opportunities satisfying your specialized prerequisites. Whether you're working on a large-scale infrastructure project or a smaller, localized endeavor, we have the expertise and equipment to deliver high-quality concrete consistently. Our ensemble of consultants teams with customers to formulate building material facilities maximizing operation, limiting waste, and accomplishing exceptional outputs. Our range covers concrete batching units, combination equipment, material management tools, pump systems, and control interfaces. Our commitment to customer satisfaction is unwavering. We provide steadfast backing from initial meetings to setup and persistent upkeep. Enable us to aid your advancement, piece by piece.Transportable Concrete Mixers: Flexible and Reliable

Amid the creation sphere, capability and elasticity are critical. Portable concrete mixing stations offer a peerless resolution to these issues, empowering builders with remarkable flexibility and transitability on projects. Unlike stationary conventional systems, these apparatuses are promptly moved across workspaces, circumventing expensive and lengthy build-up and dismantle processes. This advances seamless operations, lower delivery intervals, and significant economic benefits.

The mobility of portable cement batching units creates numerous opportunities for builders. They provide effective support for projects in isolated areas, limited metropolitan locations, or wherever traditional plants fall short. Moreover, the capacity to swiftly transfer facilities across tasks lets builders optimize assets and reduce idle periods.

- Elevated Efficiency: Minimize travel time and get projects moving faster with on-site mixing.

- Lesser Financial Burden: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Improved Flexibility: Tackle a wider range of projects in diverse locations.

With their compact design and robust performance, mobile concrete mixing plants are revolutionizing the construction industry. They provide contractors with devices crucial for achieving tasks promptly, economically, and with unfailing precision.

Meticulous Concrete Generation Using Leading Technologies

Contemporary concrete manufacturing experiences a significant transformation due to adoption of cutting-edge systems. Automated technology is implemented to ensure outstanding accuracy over the entire workflow, from primary batching to ultimate distribution. Subsequently, concrete presents enhanced solidity, curtailing refuse and maximizing material deployment. Observation systems take significant parts in obtaining continuous intelligence regarding various indicators during creation. The feedback is evaluated to detect possibilities for fine-tuning, facilitating fabricators to continuously upgrade procedures and supply uniformly excellent concrete. The benefits of precision concrete production extend beyond the manufacturing process itself. Refined elements of advanced concrete create hardy buildings, lowering refurbishment expenses and expanding facility longevity.Promoting a Green Era with Sophisticated Fabrication Equipment

The development domain witnesses a substantial shift, motivated by the imperative to lower its ecological damage. Leading-edge creation implements impact decisively this advancement towards sustainability. Electric-powered machines are becoming increasingly commonplace, reducing emissions and noise pollution. Likewise, refinement in systems fosters efficient apparatuses that allocate resources carefully. This development supports ecological preservation and amplifies effectiveness for development organizations.

The implementation of eco-friendly methods in the building industry is crucial for ensuring a habitable tomorrow. By applying modern instruments and techniques, the domain supports environmental stewardship for years ahead.

Your Dependable Collaborator in Infrastructure Projects: Robust Machinery, Qualified Help

While creating new infrastructure, reliable alliances are essential. We supply that backing. We supply extensive strong devices engineered to face intricate jobs. Our tools feature cutting-edge innovation guaranteeing peak productivity and function.

Although, we operate beyond usual apparatus suppliers. Our group of seasoned experts delivers exceptional assistance throughout the process. From design to overhaul, we support you in enhancing your construction initiatives.

- Our offerings entail detailed tutorial programs that equip your personnel for effective and protected device management

- Furthermore, we have round-the-clock professional help to answer questions and manage problems swiftly

- Our determination stresses providing tools and know-how indispensable to reach your assembly intentions

High-Capacity Cement Batching

Expansive erection tasks require cement solutions suited to withstand powerful stress and load. Sturdy cement batching techniques fulfill this obligation by manufacturing tough blends suited for spans, multistory structures, and conduits. These specialized plants utilize robust equipment capable of handling large volumes of aggregates, cement, and admixtures. Detailed appraisals preserve uniform excellence and fulfillment of stringent development norms

- Advanced control systems optimize batching accuracy and efficiency

- Applying quality materials boosts the resilience of the blend

- Robust concrete batching facilities play essential roles in construction growth affecting everyday existence

Boosting Construction Processes: Enhanced Mixing and Logistics

In the dynamic field of infrastructure, effectiveness is vital. A key aspect of achieving this lies in optimizing your mixing and delivery processes. By utilizing effective strategies, you will noticeably minimize leftovers, reduce outlays, and boost comprehensive performance. A crucial element entails opting for proper combination devices for your distinct conditions. Be it a transportable mixer for small undertakings or a sturdy unit for major projects, ensure it accommodates the amount of materials necessary. Moreover, streamline your shipment courses to cut down travel intervals and fuel costs.

- Applying a technique to track supply usage facilitates recognizing areas for advancements

- Regular maintenance of your mixing and delivery equipment is essential to ensure optimal performance and longevity

From Foundation to Finish

Throughout the sector of development, cement functions as a base of toughness and resilience. Presenting integrated services along your concrete development is our devotion. From preliminary drafting to ultimate execution,

Throughout the intensive environment of assembly, effectiveness and production are essential. To address these necessities, latest assembly apparatuses have developed to provide unbeatable effectiveness and stability. Latest premium assembly instrument solutions are equipped with progressive features increasing effectiveness and curbing environmental effects. Covering mighty trenchers and carriers to swift derricks and condensed apparatus, these instruments are built to cope with the most sophisticated development assignments seamlessly.

- Optimized actuator networks allow for smooth and precise execution, resulting in increased accuracy and reduced downtime.

- Hard-wearing segments ensure that these machines can withstand the rigors of daily use in harsh environments.

- Eco-friendly technologies minimize the environmental footprint of construction activities.

Batching Systems for Concrete: Crafted for Excellence

Concrete batch systems stand as the cornerstone of building assignments, certifying concrete is generated precisely and reliably. These elaborate configurations implement several pioneering components to increase functionality during the concrete generation phase. From the precise appraisal of substances to proficient incorporation and distribution techniques, batching operators are built to generate outstanding concrete meeting tight requirements in up-to-date construction. By automating key tasks and minimizing manual intervention, these plants ensure a consistent output while improving overall productivity.Stabilized Soil Plant Mixers Delivering Durable Foundations

Across the area of assembly, strength is fundamental. When it comes to building durable foundations, stabilized soil mixing plants emerge as a top-tier resolution. These versatile machines capably fuse solidifying additives with local ground, forming a durable structure designed to survive harsh elements and time.

Offering unparalleled strength and longevity, stabilized soil mixing plants contribute in a wide range of projects, including roads, bridges, pavements, and residential/commercial structures. By applying the inherent features of earth, these platforms enable an eco-friendly option for underpinning construction.

Cement Facility Options for Each Venture

We realize every assembly operation is original and needs bespoke building solutions. Thus, we grant assorted modifiable building material plant opportunities satisfying your specialized prerequisites. Whether executing a large-scale infrastructural plan or a tiny localized endeavor, our know-how and tools furnish high-grade concrete consistently. Our squad of technicians joins forces with clients to devise cement mixing plants improving effectiveness, curtailing loss, and securing remarkable results. Our inventory features batching modules, mixing machinery, aggregate logistics equipment, pumping hardware, and control systems. Our enthusiasm for customer pleasure is consistent. We guarantee full support from early consultation to execution and sustained maintenance. Rely on us to enhance your progress, project after project.Mobile Concrete Mixing Plants: Unmatched Flexibility and Mobility

Throughout the development domain, operation and adjustability are essential. Movable cement mixing units deliver an unequaled solution to these needs, granting constructors excellent adaptability and on-the-go capability at locations. Opposite to immobile established facilities, these plants can be efficiently relocated among locations, eliminating pricey and protracted setup and teardown steps. This advances seamless operations, lower delivery intervals, and significant economic benefits.

The transferability of portable concrete batching facilities provides extensive prospects for developers. They are capable of effectively supporting initiatives in isolated zones, congested city areas, or wherever fixed plants prove unfeasible. Also, the chance to fast relocate setups between jobs permits builders to optimize tools and reduce inactivity.

- Enhanced Output: Minimize travel time and get projects moving faster with on-site mixing.

- Lesser Financial Burden: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Enhanced Versatility: Tackle a wider range of projects in diverse locations.

Carrying their compressed form and reliable function, movable cement mixing units reshape the creation sphere. They furnish engineers with apparatus essential to accomplish ventures proficiently, inexpensively, and with reliable correctness.

Precision Concrete Production with Advanced Technology

New concrete production benefits from an important metamorphosis driven by innovative solutions. Automated technology is implemented to ensure outstanding accuracy over the entire workflow, from primary batching to ultimate distribution. This results in concrete with enhanced performance, reducing waste and optimizing resource utilization. Monitoring devices hold essential functions in gathering instantaneous data on multiple aspects during manufacturing. The feedback is evaluated to detect possibilities for fine-tuning, facilitating fabricators Concrete plant to continuously upgrade procedures and supply uniformly excellent concrete. Gains from exact concrete assembly go beyond the creation procedure itself. Improved characteristics of this cutting-edge concrete lead to tougher edifices, decreasing repair costs and lengthening structure lifespans.Establishing an Eco-Conscious Tomorrow through Innovative Development Machinery

The infrastructure field faces a rapid change, propelled by the critical necessity to decrease its environmental effect. Modern infrastructure tools hold vital functions in this transition towards environmental responsibility. Electricity-fueled equipment expands adoption, lessening pollutants and sound pollution. Also, breakthroughs in fabrication generate advanced tools that use resources prudently. These changes promote environmental protection and strengthen efficiency for assembly businesses.

The employment of eco-aware measures in the creation sphere is important for protecting a habitable earth. With the adoption of state-of-the-art devices and approaches, the industry assists in safeguarding nature for posterity.

The Key Associate in Building Ventures: Resilient Equipment, Knowledgeable Aid

To establish future construction, consistent partners are crucial. That's where we come in. We supply extensive strong devices engineered to face intricate jobs. Our tools feature cutting-edge innovation guaranteeing peak productivity and function.

But we're more than just equipment suppliers. Our staff of skilled consultants supplies unparalleled backing during all phases. From advice to restoration, we help you boost your fabrication plans.

- Our assistance covers comprehensive education plans that prepare your crew for efficient and protected machinery handling

- We provide on-site technical support to address any questions or concerns you may have

- Our commitment is on providing you with the tools and expertise you need to achieve your infrastructure development goals

Massive Concrete Manufacturing

Huge creation efforts call for concrete methods meant to endure strong pressure and tension. Heavy-duty concrete batching processes rise to this challenge by delivering high-strength mixes tailored for bridges, skyscrapers, and tunnels. Such dedicated facilities employ sturdy machinery able to process massive quantities of materials, binders, and additives. Careful evaluations maintain reliable quality and observance of tough structural codes

- Cutting-edge management solutions raise mixing consistency and efficiency

- Using elite mortars elevates the endurance of the concrete

- Sturdy concrete assembly plants contribute significantly to fabrication evolution affecting common lifestyles

Enhancing Construction Management: Optimized Mixing and Supply

Inside the brisk sector of fabrication, performance is significant. An important element to attain this involves streamlining your batching and transport workflows. With the application of proven techniques, you can markedly lessen discard, curtail spending, and elevate aggregate throughput. One factor is choosing the right mixing equipment for your specific needs. Whether it's a portable mixer for smaller projects or a heavy-duty unit for large-scale operations, ensure it can handle the volume of materials you require. What's more, adjust your shipment paths to shorten travel periods and fuel usage.

- Employing a strategy to log material application supports finding chances for enhancements

- Scheduled upkeep of your blending and distribution tools is vital to preserve best functionality and lifespan

Concrete Solutions from Start to End

Inside the universe of creation, cement holds status as a base of toughness and longevity. Delivering comprehensive solutions for every stage of your concrete journey is our passion. From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs