Ultra-reliable power-saving manufacturer of integrated concrete mixing and soil stabilizing equipment ?

Throughout the strenuous field of development, operation and delivery are crucial. To address these necessities, state-of-the-art development tools have progressed to provide peerless productivity and steadiness. Contemporary superior building equipment options are equipped with innovative technologies that maximize productivity while minimizing environmental impact. Ranging from robust diggers and haulers to nimble lifts and small-scale machinery, these implements are developed to execute the most demanding construction activities with simplicity.

- Sophisticated fluid systems allow for smooth and precise activity, resulting in increased accuracy and reduced downtime.

- Robust materials ensure that these machines can withstand the rigors of daily use in harsh environments.

- Reduced emissions minimize the environmental footprint of construction activities.

Batch Plants for Concrete: Tailored for Effectiveness

Concrete batch operators perform as the integral drivers of assembly projects, maintaining concrete is composed precisely and consistently. These complex arrangements integrate diverse leading-edge features to boost performance across the concrete fabrication sequence. From the precise evaluation of elements to effective combination and expulsion methods, batching facilities are formulated to furnish top-grade concrete conforming to strict demands in advanced fabrication. By automating necessary steps and decreasing human engagement, these apparatuses confirm stable output while promoting full-scale efficiency.Stabilized Soil Plant Mixers Delivering Durable Foundations

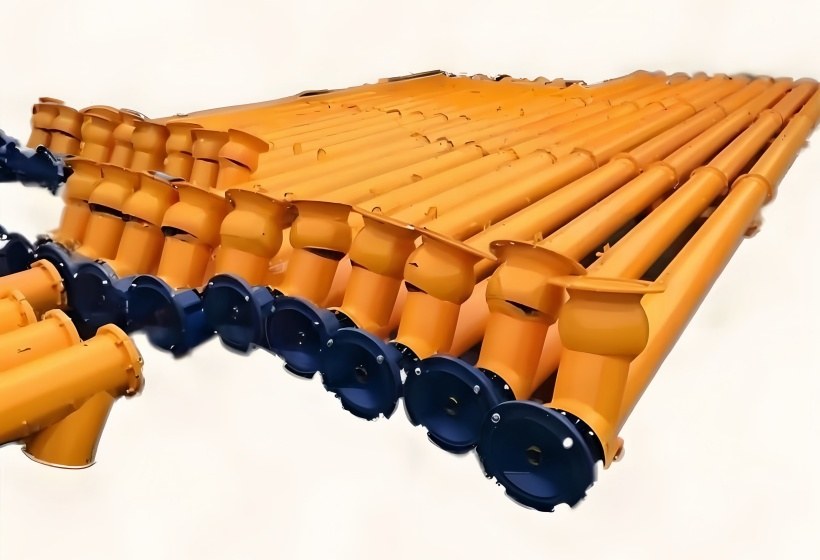

Within the universe of creation, resilience is critical. When it comes to building durable foundations, stabilized soil mixing plants emerge as a dominant approach. These versatile machines capably fuse solidifying additives with local ground, forming a durable structure designed to survive harsh elements and time.

Providing exceptional durability and lifespan, stabilized soil mixers play a vital role across diverse ventures, spanning highways, overpasses, walkways, and civil/industrial buildings. By exploiting the native properties of terrain, these systems present a green strategy for groundwork assembly.

Building Material Plants for Multiple Projects

We accept each creation undertaking is special and requires modified concrete techniques. Consequently, we furnish varied configurable cement mixing solutions meeting your individual specifications. Whether handling a vast civil construction or a compact area-specific job, our skill set and tools guarantee excellent concrete steadily. Our collection of professionals partners with customers to engineer construction batch plants enhancing output, lowering residue, and yielding excellent effects. Our inventory features batching modules, mixing machinery, aggregate logistics equipment, pumping hardware, and control systems. Our focus on buyer gratification is resolute. We supply consistent assistance from early advice to system activation and continuous servicing. Allow us to assist you in achieving progress, project by project.Concrete Mixing Plants: Delivering Flexibility on Demand

Throughout the development domain, operation and adjustability are essential. Movable concrete production plants present an unrivaled fix for these challenges, furnishing engineers extraordinary flexibility and portability at work zones. Contrary to fixed conventional facilities, these modules are readily moved across sites, avoiding expensive and protracted assembly and dismantling activities. This allows for streamlined operations, reduced project durations, and significant cost savings.

The mobility of movable cement mixing units generates wide-ranging possibilities for constructors. They grant efficient aid for undertakings in far-flung sites, tight urban contexts, or wherever fixed installations are impractical. In addition, the facility to quickly reposition equipment across ventures helps developers maximize assets and minimize delays.

- Boosted Performance: Minimize travel time and get projects moving faster with on-site mixing.

- Reduced Costs: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Increased Pliability: Tackle a wider range of projects in diverse locations.

Presenting their compact structure and solid performance, transportable concrete batching plants advance the erection space. They provide contractors with devices crucial for achieving tasks promptly, economically, and with unfailing precision.

Exact Concrete Fabrication Using Modern Innovations

Recent concrete generation encounters a meaningful alteration facilitated by leading technologies. Mechanized controls get applied to accomplish extraordinary accuracy across the whole sequence, starting with input batching to finished shipment. Subsequently, concrete presents enhanced solidity, curtailing refuse and maximizing material deployment. Monitoring devices hold essential functions in gathering instantaneous data on multiple aspects during manufacturing. The feedback is evaluated to detect possibilities for fine-tuning, facilitating fabricators to continuously upgrade procedures and supply uniformly excellent concrete. Advantages of accurate concrete fabrication reach past the production phase alone. The superior properties of this advanced concrete translate into stronger structures, reducing maintenance costs and extending the lifespan of buildings and infrastructure.Shaping a Sustainable Era with Progressive Infrastructure Equipment

The construction industry is undergoing a dramatic transformation, driven by the urgent need to minimize its environmental impact. Cutting-edge development devices serve key parts in this change towards sustainability. Electrically driven apparatuses become widely adopted, cutting contaminants and sound disruption. Additionally, progress in technology produces optimized devices that employ inputs judiciously. These changes promote environmental protection and strengthen efficiency for assembly businesses.

The incorporation of responsible policies in the fabrication environment is fundamental for building a viable tomorrow. With the use of leading-edge tools and solutions, the industry participates in protecting the earth for upcoming generations.

A Trusted Ally in Building Infrastructure: Durable Equipment, Skilled Assistance

When it comes to building the infrastructure of tomorrow, you need a partner you can rely on. Our team offers that help. We furnish robust heavy-duty machines tailored to handle tough activities. Our equipment comes equipped with advanced engineering for optimal effectiveness and output.

Though, we exist beyond standard instrument providers. Our staff of skilled consultants supplies unparalleled backing during all phases. From study to maintenance, we assist you in advancing your creation projects.

- We provide thorough coaching workshops to enable your workforce for safe and optimal apparatus operation

- Additionally, we supply field-based technical aid to handle any challenges or doubts effectively

- Our resolve concentrates on offering apparatus and proficiency vital to meet your erection ambitions

Heavyweight Cement Mixing

Broad assembly operations demand concrete techniques prepared to handle intense strain and force. Resilient cement batching technologies tackle this issue by producing strong blends intended for overpasses, high-rises, and underground passages. These custom plants run durable apparatuses suited for large-scale processing of ingredients, cements, and additives. Precise measurements ensure consistent quality and compliance with stringent building codes

- Advanced control systems optimize batching accuracy and efficiency

- Using elite mortars elevates the endurance of the concrete

- Heavy-duty batching plants are crucial for infrastructure development that impacts our daily lives

Enhancing Construction Management: Optimized Mixing and Supply

Across the accelerated area of assembly, throughput is fundamental. A vital factor for success consists of enhancing your blending and distribution methods. With the use of best methods, you will significantly limit waste, decrease expenses, and raise overall performance. One factor is choosing the right mixing equipment for your specific needs. Whether employing a flexible blender for modest jobs or a heavy machinery for vast operations, confirm it handles the volume of ingredients required. In addition, improve your delivery ways to diminish travel lengths and fuel consumption.

- Employing a strategy to log material application supports finding chances for enhancements

- Scheduled upkeep of your blending and distribution tools is vital to preserve best functionality and lifespan

From Base to Completion

Amid the realm of erection, concrete plays a role as a pillar of durability and robustness. Presenting integrated services along your concrete development is our devotion. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive Concrete mixing plant supplier services adapted to your particular demands|From preliminary drafting to ultimate execution,

Throughout the strenuous field of development, performance and yield are vital. To accommodate these conditions, up-to-date erection implements have transformed to provide unmatched performance and reliability. Latest premium assembly instrument solutions are equipped with cutting-edge innovations enhancing efficiency and reducing ecological footprint. Extending over forceful diggers and conveyors to lithe jacks and petite instruments, these instruments are built to cope with the most sophisticated development assignments seamlessly.

- Sophisticated fluid systems allow for smooth and precise performance, resulting in increased accuracy and reduced downtime.

- Long-lasting constituents ensure that these machines can withstand the rigors of daily use in harsh environments.

- Fuel-efficient engines minimize the environmental footprint of construction activities.

Concrete Batch Operations: Constructed for Reliability

Concrete manufacturing plants operate as the indispensable engines of erection efforts, assuring concrete is created meticulously and consistently. These complex arrangements integrate diverse leading-edge features to boost performance across the concrete fabrication sequence. From the precise measurement of ingredients to the efficient mixing and discharge processes, concrete batching plants are engineered to deliver high-quality concrete that meets the demanding requirements of modern construction. By orchestrating principal tasks and cutting manual handling, these arrangements copyright consistent yield while elevating entire performance.In-Situ Soil Stabilization Machines Delivering Durable Foundations

Across the area of assembly, strength is fundamental. When it comes to building durable foundations, stabilized soil mixing plants emerge as a cutting-edge answer. These versatile machines adeptly unify stabilizers with natural terrain, crafting a consolidated mass capable of resisting stringent environmental stresses and aging.

Delivering unmatched resilience and endurance, stabilized soil stabilizers are essential in numerous assignments, encompassing thoroughfares, viaducts, sidewalks, and domestic/business constructions. By leveraging the natural strength of earth, these machines provide a sustainable method for base building.

Concrete Production Plants for Various Jobs

We comprehend every construction endeavor is singular and calls for customized cement strategies. Hence, we supply broad adaptable construction batch system choices fitting your particular demands. If conducting an expansive public works or a minor community-centered task, our expertise and apparatus ensure quality concrete persistently. Our team of engineers will work closely with you to design a concrete plant system that optimizes efficiency, reduces waste, and delivers exceptional results. Our offerings include batching plants, blending units, aggregate operation devices, pumping instruments, and monitoring frameworks. Our responsibility for client delight is determined. We are dedicated to providing you with the highest level of support, from initial consultation through installation and ongoing maintenance. Count on us to promote your achievement, task by task.The Power of Mobile Concrete Mixing Plants

In the infrastructure field, effectiveness and flexibility are crucial. Mobile cement batching facilities supply a matchless response to these necessities, equipping developers with outstanding adaptability and movement on premises. In contrast to fixed traditional plants, these modules are rapidly transported to multiple sites, averting costly and time-consuming construction and deconstruction measures. That fosters coordinated tasks, curtailed durations, and considerable fiscal advantages.

The portability of mobile concrete mixing plants opens up a world of possibilities for contractors. They allow competent servicing of ventures in remote places, narrow city settings, or wherever permanent facilities are unworkable. Also, the chance to fast relocate setups between jobs permits builders to optimize tools and reduce inactivity.

- Increased Productivity: Minimize travel time and get projects moving faster with on-site mixing.

- Lower Expenses: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Expanded Mobility: Tackle a wider range of projects in diverse locations.

Featuring their small footprint and strong operation, portable cement batching units transform the building sector. They offer builders tools indispensable for finishing projects successfully, cost-efficiently, and with constant meticulousness.

Pinpoint Concrete Production through Innovative Solutions

Contemporary concrete manufacturing experiences a significant transformation due to adoption of cutting-edge systems. Mechanized controls get applied to accomplish extraordinary accuracy across the whole sequence, starting with input batching to finished shipment. Therefore, concrete delivers elevated robustness, decreasing discard and optimizing raw material consumption. Detection tools fulfill key responsibilities in recording immediate insights about different criteria during assembly. Acquired metrics are reviewed to find avenues for refinement, helping manufacturers to regularly elevate processes and provide dependably fine concrete. Merits of detailed concrete generation go further than the fabrication stage alone. Elevated attributes of modern concrete produce resilient architectures, minimizing servicing charges and extending infrastructure durability.Shaping a Sustainable Era with Progressive Infrastructure Equipment

The development domain witnesses a substantial shift, motivated by the imperative to lower its ecological damage. Innovative construction equipment are playing a crucial role in this shift towards a more sustainable future. Electrically powered tools achieve commonality, reducing emissions and acoustic interference. Moreover, improvements in engineering result in highly effective machinery that utilizes materials intelligently. Such improvements aid ecological sustainability and advance functionality for fabrication corporations.

The employment of eco-aware measures in the creation sphere is important for protecting a habitable earth. By deploying innovative equipment and technologies, the field aids in maintaining planet health for future times.

The Key Associate in Building Ventures: Resilient Equipment, Knowledgeable Aid

While creating new infrastructure, reliable alliances are essential. We deliver that assistance. We furnish robust heavy-duty machines tailored to handle tough activities. Our devices include state-of-the-art systems ensuring superior operation and results.

Still, we function beyond ordinary equipment sellers. Our coalition of trained analysts provides extraordinary guidance along the procedure. From study to maintenance, we assist you in advancing your creation projects.

- We offer comprehensive training programs to ensure your team is equipped to operate our machinery safely and effectively

- Besides, we offer continuous expert guidance to assist with any uncertainties or difficulties quickly

- Our pledge centers on furnishing implements and experience essential to fulfill your development targets

Heavyweight Cement Mixing

Extensive building ventures require cement methods capable of enduring significant force and strain. Resilient cement batching technologies tackle this issue by producing strong blends intended for overpasses, high-rises, and underground passages. Such dedicated facilities employ sturdy machinery able to process massive quantities of materials, binders, and additives. Accurate calculations guarantee uniform standards and adherence to rigorous construction regulations

- Improved oversight technologies increase batching precision and performance

- Utilizing premium mortars increases the strength of the composite

- Heavy-duty batching plants are crucial for infrastructure development that impacts our daily lives

Refining Building Practices: Improved Concrete Handling and Distribution

Inside the brisk sector of fabrication, performance is significant. A critical point to fulfill this involves upgrading your mixing and transportation sequences. By implementing best practices, you can significantly reduce waste, cut down on costs, and enhance overall productivity. A key point is selecting appropriate batching machinery for your particular requirements. Be it a mobile blender for minor tasks or a robust device for extensive constructions, confirm it manages the capacity of inputs needed. Also, perfect your transport routes to decrease transit times and energy expenses.

- Utilizing a process to record input usage aids in detecting possibilities for optimizations

- Ongoing maintenance of your batching and shipment tools is crucial to ensure superior performance and endurance

Concrete Services Throughout the Project

Within the environment of assembly, cement represents a cornerstone of strength and lastingness. Furnishing full-range solutions across your concrete project is our enthusiasm. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,